Custom Fabrication

Iour profitability depends on the accuracy of your work. Every misfit is a loss of materials, labor, and time. Our services eliminate these painful inefficiencies, allowing you to fabricate with confidence and take on more custom jobs.

-

We solve the pain of misfits and material waste. Our precise reverse engineering services create highly accurate 3D digital models from existing physical parts or field conditions, ensuring new components integrate perfectly. This prevents re-fabrication due to errors and can save thousands to tens of thousands of dollars per complex custom job.

-

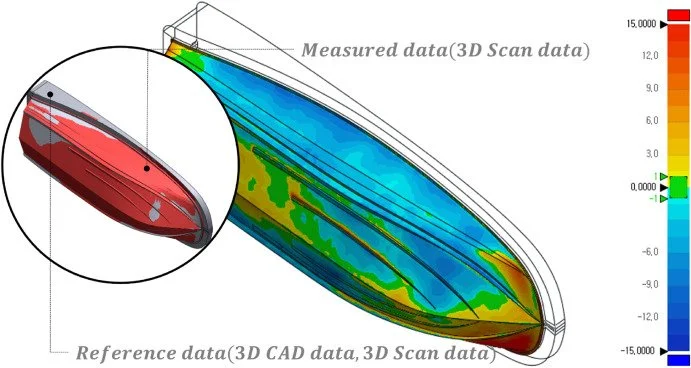

We solve the problem of downstream quality issues and customer dissatisfaction. Our non-contact, high-accuracy dimensional inspection services compare scanned parts to their CAD models in minutes, allowing you to identify critical errors before shipping or final assembly. This prevents costly field rework, logistical nightmares, and saves significant material and labor costs.

How We Deliver Cost & Time Savings in Custom Fabrication

Real-World Applications

Advanced Reverse Engineering:

Create highly precise 3D digital models of existing physical parts, products, or tooling for which no CAD data exists, ensuring manufacturability.

Comprehensive Quality Control & Inspection:

Perform non-contact, high-accuracy dimensional inspection by comparing scanned parts to their CAD models.

Optimized Tooling & Fixture Design/Verification:

Accurately inspect and then design/modify molds, dies, jigs, and fixtures.

Accelerated Product Development & Prototyping:

Rapidly capture and digitize physical prototypes, enabling faster iteration and concept validation.

Digital Archiving & Replication:

Create precise digital libraries of parts and products for future reference, modification, or re-manufacturing.

Custom Fabrication:

Leverage scan data for custom parts, including sheet metal design and mechanical detailing.